Heat treatments

PACD - PLASMA ASSISTED

CARBON DIFFUSION

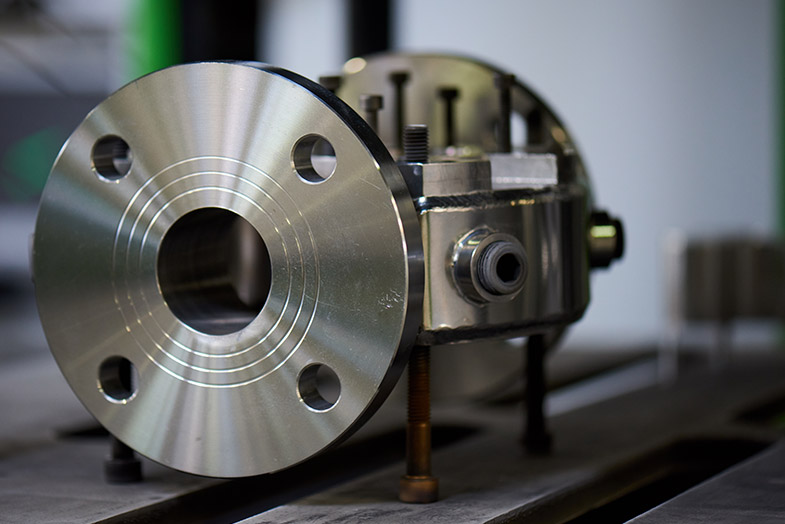

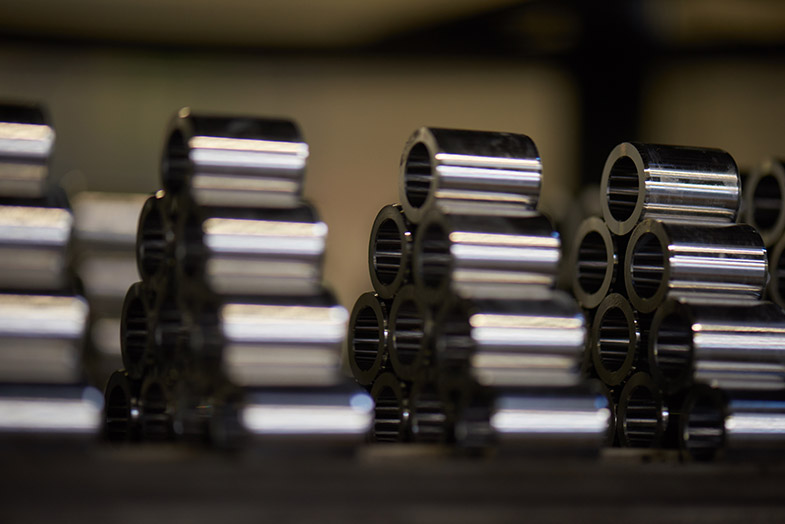

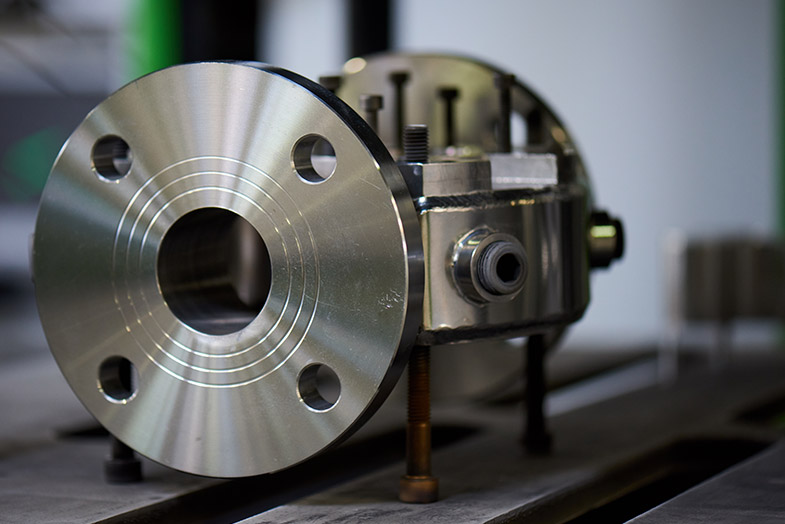

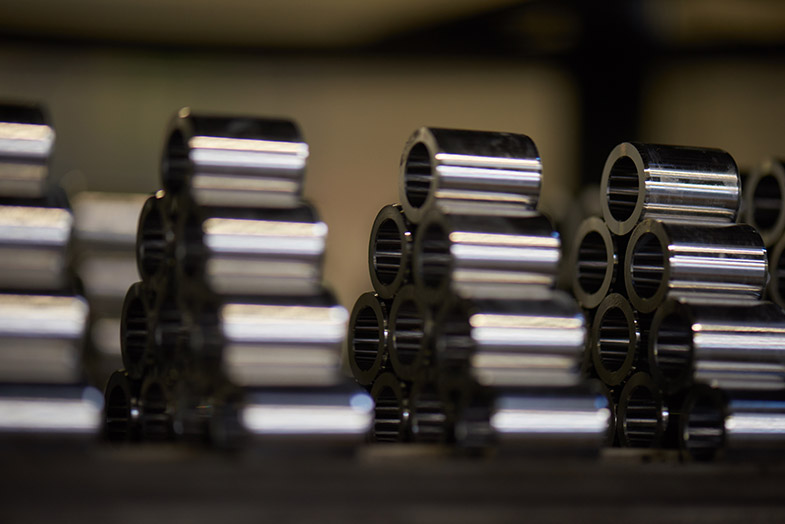

The use of austenitic stainless steels for products with elevated corrosion resistance is typical of many industries is typical of many industries from aeronautics to petrochemicals, food to biomedicals.

For many years there have been efforts to augment the wear resistance of such materials, with thermochemical treatments like ionic nitriding, which, thanks to the capacity of plasma to break the protective oxide surface film which otherwise inhibits the any form of surface reaction to hardening treatments, results in the diffusion of nitrogen into the steel's crystalline matrix, thus significantly increasing the hardness of the material and hence its resistance to wear.

However, nitriding may result in the formation of chrome nitrides due to the diffusion of nitrogen, which increases the wear resistance of the material, but considerably diminishes its corrosion resistance due to the smaller amount of chrome available for passivation.

To overcome this limitation, Vacuum has developed a PACD process (Plasma Assisted Carbon Diffusion) for low temperature plasma hardening (at around 300°C) which diffuses carbon into the matrix of the austenite in supersaturated conditions, thus ensuring surface hardening while limiting the loss of corrosion resistance of the material itself.

Developed by Vacuum PACD (Plasma Assisted Carbon Diffusion), achieves precisely these objectives.

This process results in increased surface hardness due to the distortion of the cubic matrix of austenite, without however forming chrome carbides. The result is a significant increase in the surface hardness (up to 1000 HV0.05 for AISI 304, over 1100 HV0.05 for AISI 316) while maintaining good corrosion resistance.

This is a diffusion treatment, not a coating, so there is no risk of it flaking off.

The hardened zone is typically around 20 um thick, and no precipitated carbides are to be found, so that the resistance to corrosion of the material is not compromised.

ADVANTAGES:

- Increased surface hardness;

- Improved corrosion resistance.