Heat treatments

PRECIPITATION HARDENING (AGING)

Precipitation hardening is obtained by means of a heat treatment in several stages, i.e.: solubilisation, hardening and aging.

Solubilisation dissolves a maximal amount of Cu (15-5PH, 17-4PH) and Mo (13-8Mo PH) and the subsequent aging forms precipitates which stress the matrix, thus increasing its specifications (hardness, Rm. etc.).

For finished parts, given the increasing demand for special finishes, we have dedicated equipment and validated thermal cycles which enhance the shine and brilliancy of the finished product to the client's requirements.

The following materials are subjected to precipitation hardening:

- Copper alloys (CuBe);

- Nickel alloys (Inconel 718);

- CRES alloys (Corrosion Resistant Steels 13-8-MO, 15-5-PH, 17-4-PH, 17-7-PH);

- Maraging steels.

ADVANTAGES:

- Increased mechanical strength at ambient and very high temperatures;

- Good corrosion resistance combined with excellent mechanical characteristics. (for CREAS alloys).

We also offer aging treatments for Maraging steels.

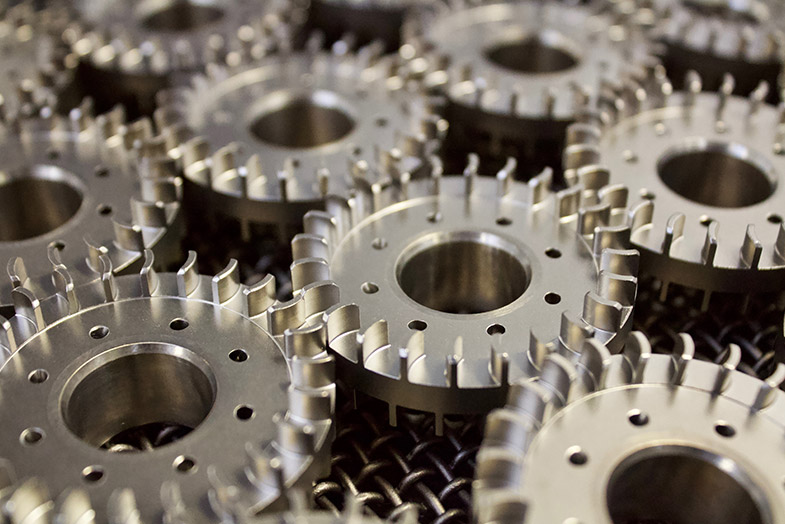

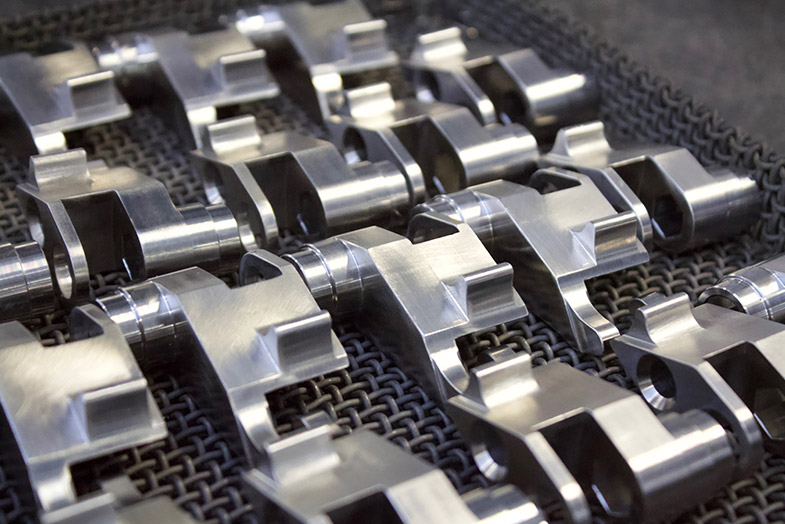

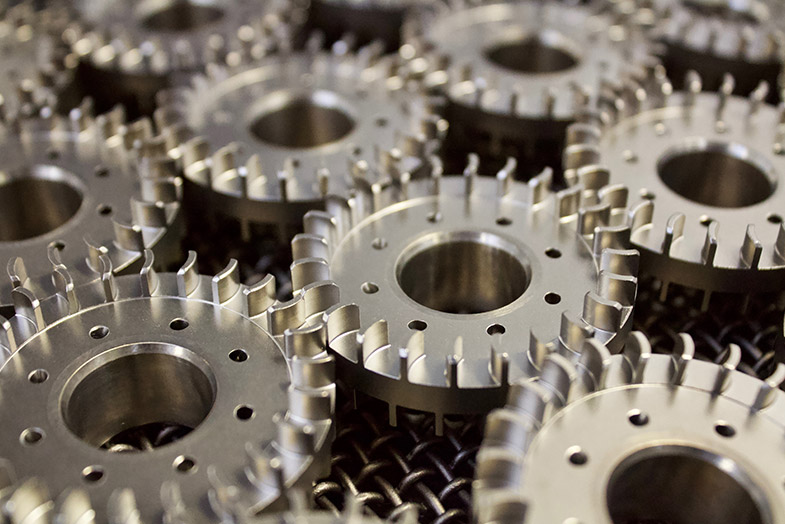

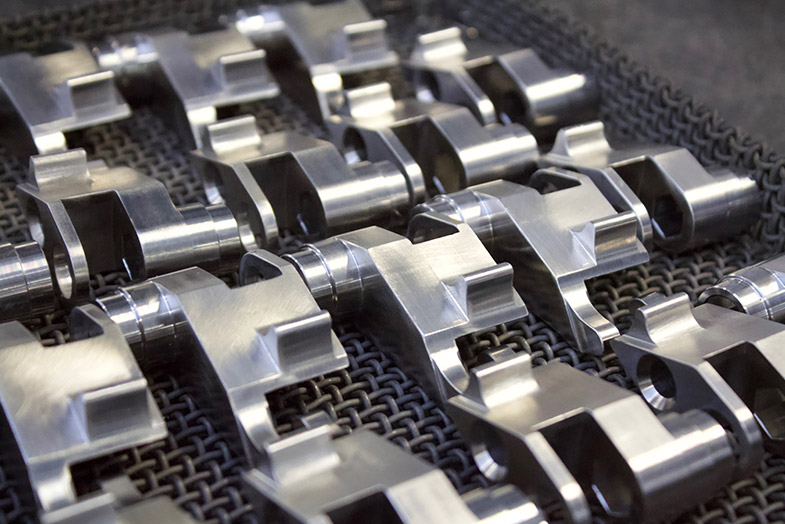

Maraging steels are steels with very high tenacity and elasticity combined with excellent mechanical strength. We normally use precipitation hardening with such steels. Maraging steels are mainly used in race cars, aeronautics, and also in the manufacture of food processing and packaging equipment when the parts must be highly resilient and tenacious while still having excellent wear resistance.