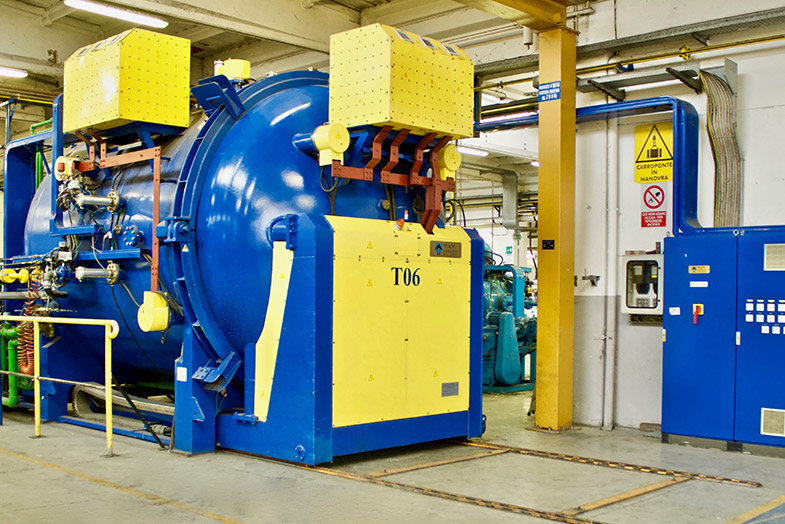

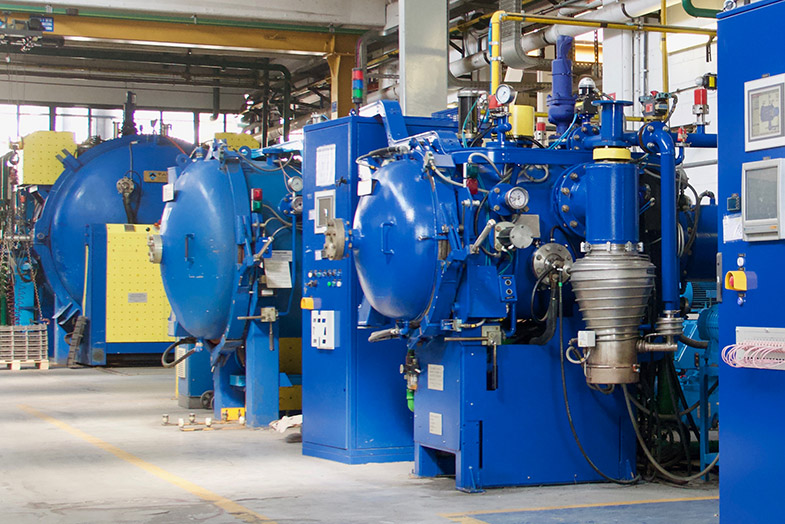

Heat treatments

VACUUM

HARDENING

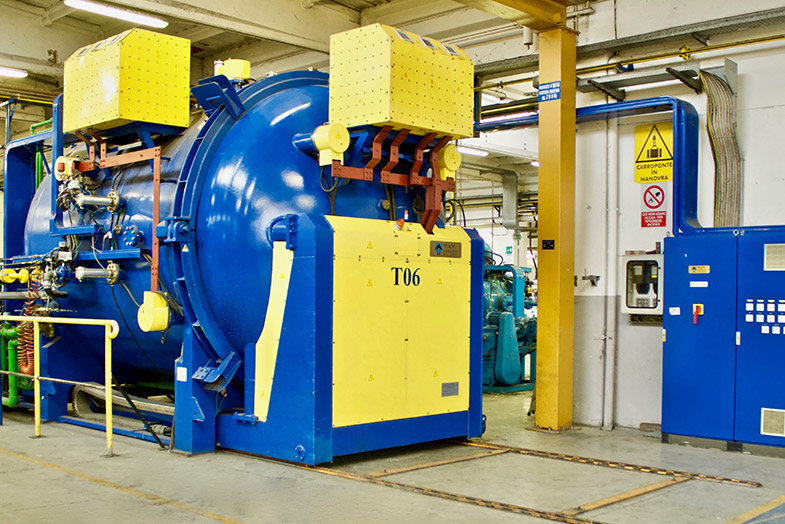

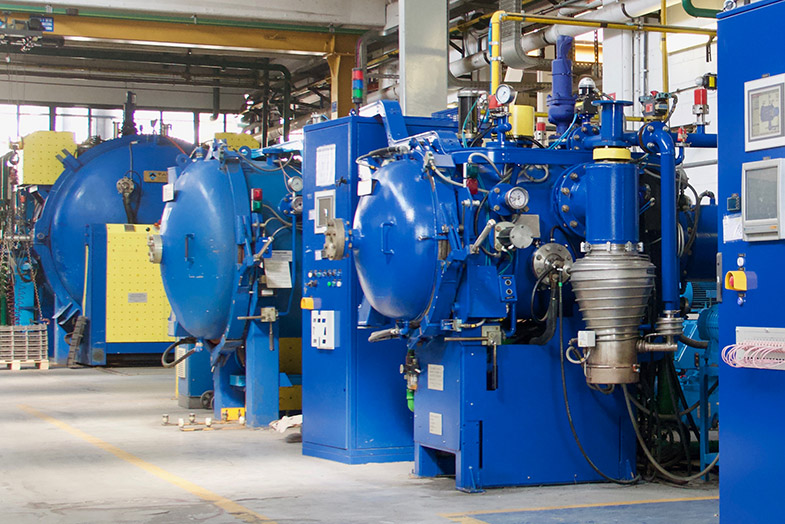

The company's strongpoint, vacuum hardening is one of the most common treatments.

Over the years we have acquired the equipment needed to respond to our clients' ever more detailed specification of the mechanical properties of the material resulting from the heat treatment process.

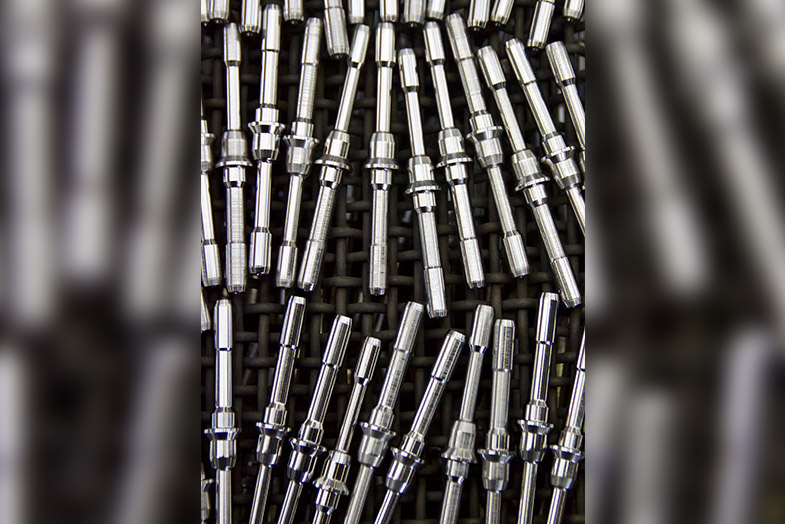

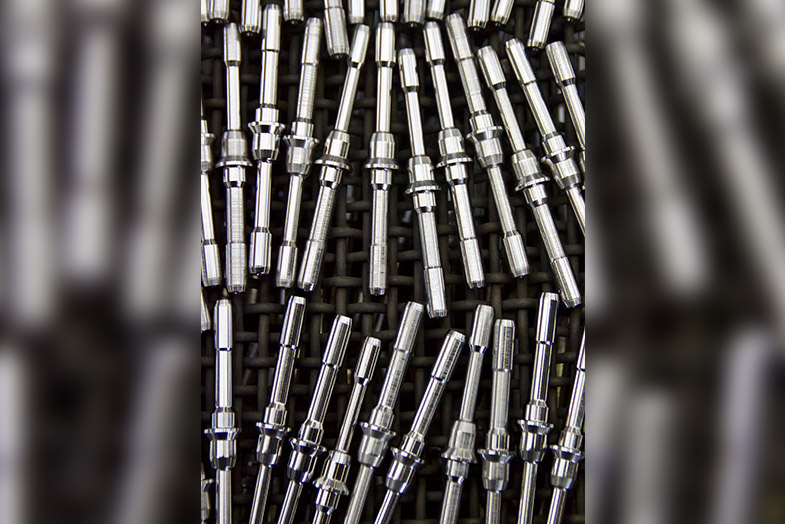

Vacuum hardening technology assures the highest quality finish and mechanical specification of treated components. Variations in shape and dimensions (due to deformation) are reduced to a minimum.

Materials:

- Tool steels

- Martensitic stainless steels

- High speed and super high speed steels

The use of vacuum combined with pressurised gas cooling as the basic technology offers numerous advantages:

- Total control of all thermal cycle parameters;

- Treatment adaptable to the material, geometry and final specifications of the part;

- No oxidation or decarburisation;

- Reduced deformations;

- Respect for the environment and cleanliness;

- Very safe processing;

- Tools and dies are made wear and heat resistant and maintain their solidity;

- Parts requiring low roughness grinding acquire the desired workability;

For all these reasons, if the parts are in martensitic stainless steel, their corrosion resistance is better only after heat treatment.

The plant is equipped with the most advanced process control and registration systems, compliant with stringent aerospace and Nadcap regulations (AMS2750).